DRY BULK BLENDING

& LIQUID ADDITIONS

- BATCH OR CONTINUOUS

- SANITARY OR INDUSTRIAL

- EXTREME DURABILITY

ROTARY BATCH MIXERS

- Gentle 4-way mixing action for powder/bulk materials blending

- Rapid batch cycle times with no classification or degradation

- Capacities from 5 to 600 cu ft

(142 L to 17 m3) - Ideally suited for liquid spray additions and coating applications

RIBBON/PADDLE/PLOW BLENDERS

- Ruggedly built, single agitator blenders

- Capacities up to 10,000 cubic feet (283 m3)

- Available with easily removable flanged agitator or sanitary designs with removable end panels

- Double helical ribbon, plow or paddle designs

- Optional: internal sprayline, heating and cooling jackets, multiple cover and discharge designs, special sizing or drive requirements

ROTARY BATCH MINI MIXERS

- Gentle 4-way mixing action for powder/bulk materials blending

- Rapid batch cycle times with no classification or degradation

- Capacities from 0.25 to 15 cubic feet

(7 to 425 liters) - Ideally suited for liquid spray additions and coating applications

FLUIDIZED BED MIXERS

- Ultra-fast mixing — one minute typical

- More gentle than other agitated mixers

- Uniform mixing regardless of bulk density or particle size/shape

- Allows low-to-high volumes of liquid additions

- Discharges rapidly and thoroughly

CYLINDRICAL PLOW BLENDERS

- High-intensity batch blending of bulk materials that do not readily intermix, faster than with conventional ribbon/paddle/plow blenders

- Jackets, choppers, and ports or spray heads for liquid additions/injections

- 1 to 400 cu ft (28 to 11,327 liters) useable capacity

- 1 to 200 HP (0.75 to 149.1 kW) in direct or foot-mounted drives

- Typical applications: foods, pharmaceuticals, nutraceuticals, wood, plastics, bakery products, detergents

VEE CONE BLENDERS

- Uniform blends achieved in 15 to 30 minutes

- Complete discharge with no residual

- Capacities from 1 cup (0.5 liters) to over 200 cu ft (5,663 liters)

- Rapid sanitizing: smooth internal surfaces free of baffles, shafts or bearings

- More gentle than agitated machines

VARIABLE INTENSITY CONTINUOUS BLENDERS

- Single agitator style, high or low speed

- Internal agitator paddles can be adjusted 180° for high impact, pin or pug mill applications & can be gear reduced for inline gentle mixes

- Spray ports available for large additions of liquids

- Capacities up to 3,000 cubic feet (85 m3) per hour

ROTARY CONTINUOUS MIXERS

- Rotary style continuous blender with removable internal mixing flights

- Gentle thorough mixing action, no product degradation, with excellent coating capabilities

- Dust tight seal design, with sanitary construction available

- Capacities up to 3000 cubic feet (85 m3) per hour

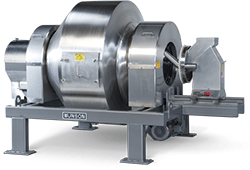

ROTARY BATCH MIXERS

Blend dry bulk solids with or without liquid additions quickly, uniformly and gently, with total discharge and no cross-contamination

Rotary Batch Mixers are available in useable capacities to 600 cu ft (17 m3). Shown is a

40 cu ft (1 m3) sanitary stainless steel model with retractable inlet, for blending of spices.

The MUNSON® Rotary Batch Mixer delivers uniform particle distribution, uniform liquid additions, cycle times under 3 minutes, gentle product handling, the lowest energy consumption, and complete discharge with no segregation. It also cleans and sanitizes quickly and easily preventing cross-contamination.

Munson's unique, four-way mixing action gently folds, tumbles, cuts and turns the material, producing a thorough blend in only 1 to 3 minutes, while imparting minimal energy and intensity to the product.

The same blending action prevents segregation regardless of particle sizes, shapes or bulk densities, and provides an ideal fluid bed for liquid additions.

Unlike stationary mixers with agitators, MUNSON Rotary Batch Mixers produce homogeneous blends with no shear, discharge completely with no stratification and have no internal shafts or shaft seals to contact material.

Internal mixing flights direct material towards and through a stationary discharge gate which, together with multiple clean-out doors and unrestricted access to all internal surfaces, allows thorough cleaning and sanitizing in minutes.

This 90 cu ft (2.5 m3) abrasion-resistant Rotary Batch Mixer blends dry cement mixes in less than three minutes, gently and efficiently with total uniformity.

- 1 to 3 minute cycle times

- Uniform dry blends and liquid additions

- Gentle mixing

- Total discharge with no segregation

- Ultra-fast cleaning and sanitizing

- Full interior access

- Low energy costs

- Stationary inlet and outlet

- Wide range of flexible capacities

- Dust-tight operation

- Long life with minimal maintenance

Capacities range from 5 to 600 cu ft (142 liters to 17 m3), with equal mixing efficiency at 100% of rated capacity to as low as 15% (33% with liquid additions), providing unsurpassed flexibility.

This superior combination of attributes makes the MUNSON Rotary Batch Mixer ideal for a broad range of applications, from pharmaceutical, nutraceutical and food applications requiring absolute cleanliness, to minerals, glass and concrete blending requiring extraordinary durability.

Specifications

(Click here for model dimensions)

| MODELS AVAILABLE IN TS, TH AND THC DESIGNS BASED ON BULK DENSITY |

BATCH VOLUME CU FT / M3 |

TOTAL VOLUME CU FT / M3 |

POWER REQUIREMENTS | |

|---|---|---|---|---|

| TYPICAL MIN. POWER FOR LIGHTER MAT'LS (HP / kW) |

TYPICAL MAX. POWER FOR HEAVIER MAT'LS (HP / kW) |

|||

| 700-5 | 5 / 0.14 | 10 / 0.28 | 2 / 1.47 | 2 / 1.47 |

| 700-10 | 10 / 0.28 | 20 / 0.57 | 5 / 3.73 | 5 / 3.73 |

| 700-15 and GB-10* |

15 / 0.42 | 29 / 0.82 | 5 / 3.73 | 5 / 3.73 |

| 700-20 | 20 / 0.57 | 48 / 1.36 | 5 / 3.73 | 5 / 3.73 |

| 700-35 and GB-20* |

35 / 1.00 | 76 / 2.15 | 7.5 / 5.59 | 10 / 7.46 |

| 700-50 and GB-35* |

50 / 1.42 | 105 / 2.97 | 7.5 / 5.59 | 10 / 7.46 |

| 700-75 and GB-50* |

75 / 2.12 | 152 / 4.30 | 10 / 7.46 | 15 / 11.19 |

| 700-90 and GB-60* |

90 / 2.55 | 174 / 4.93 | 10 / 7.46 | 15 / 11.19 |

| 700-110 and GB-75* |

110 / 3.11 | 218 / 6.17 | 15 / 11.2 | 20 / 14.91 |

| 700-140 and GB-90* |

140 / 3.96 | 271 / 7.67 | 20 / 14.9 | 25 / 18.6 |

| 700-180 and GB-120* |

180 / 5.10 | 357 / 10.11 | 30 / 22.4 | 40 / 29.8 |

| 700-250** | 250 / 7.08 | 500 / 14.16 | 40 / 29.8 | 50 / 37.3 |

| 700-300** | 300 / 8.50 | 581 / 16.45 | 40 / 29.8 | 60 / 44.7 |

| 700-400** | 400 / 11.33 | 800 / 22.65 | CONSULT FACTORY | CONSULT FACTORY |

| 700-600** | 600 / 16.99 | 1200 / 33.98 | CONSULT FACTORY | CONSULT FACTORY |

*Specialized "GB" models for glass batching, refractories and other poor-flowing, highly abrasive materials.

**Dual drive units available for ultra-dense materials.

The above power requirements are generalizations that may not apply to your application. Please consult factory.

WARNING: In order to clearly show details of machines, some covers, shields, doors and guards have either been removed or are shown in the open position in photographs throughout this brochure. All protective devices must be properly installed before operation of equipment. Failure to do so may result in personal injury and/or damage to the machine components.

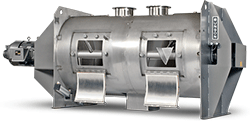

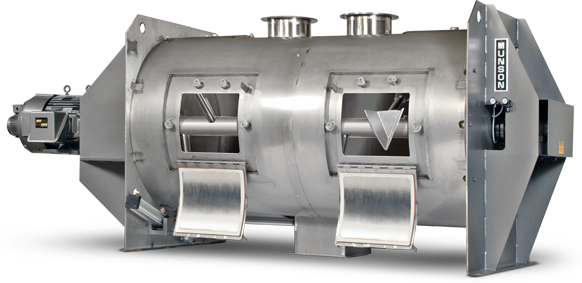

RIBBON/PADDLE/PLOW BLENDERS

Blend dry solids, pastes and slurries in 5 to 10 minutes. Versatile, economical and effective when low-energy agitation is required

MUNSON 25 cu ft (0.7 m3) Stainless Steel Ribbon Blender

MUNSON Ribbon, Paddle and Plow Blenders feature stationary U-shaped vessels with flat cover sections on top and a discharge valve on the bottom, and a single, horizontally-oriented shaft rotating on external bearings, with radial arms supporting ribbon, paddle or plow agitator elements, each of which offers distinct benefits across a diverse range of applications.

These blenders force agitators through stationary material, which accelerates the dispersion of individual particles into liquids. As a result, they can blend solids with solids, as well as solids with low or high percentages of liquids to produce smooth pastes or slurries.

From sanitary blenders for pharmaceutical and food products on a laboratory, pilot plant or production scale, to robust, super-duty machines for soil reclamation, building materials and oil sludge treatment, MUNSON custom-engineers each Ribbon, Paddle and Plow Blender to deliver maximum performance for your specific application.

Design and Construction

Mixing capacity is approximately 70 to 80% of total vessel volume, providing: 1) ample space for material flow on the upswing side of the agitator, 2) complete agitator contact with batch materials and 3) proper distancing of an optional spray manifold for introducing liquid additions on the downswing side of the agitator, resulting in uniform solids/liquids distribution.

MUNSON Horizontal Agitated Blenders are offered with ribbon, paddle and plow agitators in many specialized designs to suit each application with top efficiency.

In addition to full-scale machines, MUNSON offers small-scale equipment such as this 1 cu ft (.03 m3) ribbon blender, for laboratory testing, pilot plants and small production runs.

One-piece welded construction, together with heavy-gauge walls and fully reinforced end panels, make these vessels extremely rigid, allowing for exceptionally tight agitator-to-vessel wall tolerances. This, in turn, minimizes residual product in the trough following discharge, reducing material waste and cleaning time.

MUNSON blenders are available constructed of a variety of materials, including but not limited to carbon steel, #304/304L and #316/316L stainless steel, abrasion-resistant steel (AR-200/235), duplex stainless, Hastelloy, titanium and other exotics.

Interior finishes range from a standard clean mill finish to ultra-high sanitary finishes, including 2B, #4, and #7 mirror pharmaceutical finishes to sanitary USDA Dairy finishes with electroplating and chemical passivation. Interior weld polishes range from standard 80 grit clean welds to 240 grit radiused and polished welds.

Specifications

(Click here for model dimensions)

| Model | Mixing Capacity (Cu Ft) (m3) |

Total Vessel Volume (Cu Ft) (m3) |

Standard Agitator Speed (RPM) |

Standard Horse Power (HD Series)** (kW) |

|---|---|---|---|---|

| 11 | 1 0.03 |

1.5 0.04 |

100 | 1 0.75 kW |

| 12 | 2 0.056 |

3 0.085 |

100 | 1.5 1.1 |

| 1.5-3 | 5 0.14 |

7 0.19 |

70 | 3 2.24 |

| 24 | 12 0.34 |

17 0.48 |

50 | 5 3.73 |

| 2.5-5 | 25 0.71 |

33 0.93 |

40 | 10 7.45 |

| 36 | 35 1.00 |

56 1.59 |

33 | 15 11.19 |

| 3.5-7 | 65 1.84 |

87 2.46 |

30 | 25 18.6 |

| 3.5-9 | 85 2.40 |

112 3.17 |

30 | 30 22.37 |

| 48 | 100 2.83 |

129 3.65 |

25 | 40 29.83 |

| 4.5-9 | 150 4.25 |

183 5.18 |

22 | 60 44.74 |

| 510 | 200 5.66 |

248 7.02 |

20 | 75 55.93 |

| 512 | 250 7.08 |

297 8.41 |

20 | 75 55.93 |

| 612 | 350 9.91 |

445 12.60 |

17 | 100 74.57 |

| 6.5-12 | 400 11.33 |

517 14.64 |

13 | 125 73.55 |

| 6.5-15 | 500 14.16 |

647 18.32 |

13 | 150 93.2 |

| 716 | 600 16.99 |

785 22.23 |

11 | Determined by Application |

| 816 | 800 22.65 |

1,100 31.15 |

10 | Determined by Application |

| 820 | 1,000 28.32 |

1,300 36.81 |

10 | Determined by Application |

| 918 | 1,150 32.56 |

1,466 41.51 |

9 | Determined by Application |

WARNING: In order to clearly show details of machines, some covers, shields, doors and guards have either been removed or shown in the open position. Be sure that all protective devices are properly installed before operating equipment. Failure to follow this instruction may result in personal injury and/or damage to the machine components.

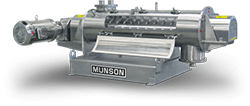

ROTARY BATCH

MINI MIXERS

Gently blend dry materials in 2 to 3 minutes, add liquids uniformly, discharge with no segregation and sanitize quickly — on a laboratory, pilot plant or small-production scale

This 5 cu ft (142 liter), sanitary Rotary Batch Mini Mixer model MX-5-SS is equipped

with a large access door as standard. Options shown include Swing-Away Intake Chute, Discharge Chute with frame extension, and all stainless steel construction

including support frame and casters.

MUNSON® Rotary Batch Mini Mixers deliver the same unique advantages as larger in-line models, but in capacities from 0.25 to 15 cu ft (7 to 425 liters) for off-line laboratory, pilot plant, small-production or pre-blending applications.

The four-way mixing action gently tumbles, turns, cuts and folds the material, producing a thorough blend in only 2 to 3 minutes, while preventing degradation by imparting minimal energy and intensity to the product.

This blending action also prevents segregation during discharge regardless of particle sizes, shapes or bulk densities, and provides an ideal fluid bed for liquid additions.

Unlike stationary mixers with agitators, Rotary Batch Mini Mixers produce homogeneous blends with no shear, discharge completely with no stratification, and have no internal shafts or shaft seals to contact material.

Internal mixing flights direct material towards and through a discharge gate for complete evacuation which, together with unrestricted interior access, allows thorough cleaning and sanitizing in minutes.

Mixing efficiency at 100% of rated capacity to as low as 5% (33% with liquid additions) remains constant, providing unsurpassed flexibility. In addition, results obtained are scalable to Munson's high capacity in-line Rotary Batch mixers.

This superior combination of attributes makes the Rotary Batch Mini Mixer ideal for a broad range of laboratory, pilot plant and small-production applications, from pharmaceutical, nutraceutical and food applications requiring absolute cleanliness, to minerals, glass and concrete blending requiring extraordinary durability.

MUNSON also offers in-line Rotary Batch mixers that have stationary inlets and outlets and capacities from 5 to 600 cu ft (142 liters to 17 m3), and Rotary Continuous Mixers with capacities from 25 to 5000 cu ft/h (708 liters to 142 m3/h).

_276w.jpg)

With a 0.25 cu ft (7 liter) batch capacity, model MX-1/4 is Munson's smallest Rotary Batch Mini Mixer. It is equipped as standard with manual tilt and removable drum, with results scalable to models having capacities to 600 cu ft (17 m3), making it ideal for countertop testing.

Specifications

(Click here for model dimensions)

| MODELS | BATCH VOLUME CU FT/LITERS |

DRUM VOLUME CU FT/LITERS |

HP/kW | MAX BATCH WEIGHT |

SHIPPING WEIGHT LB/KG |

|---|---|---|---|---|---|

| MX-1/4 | 0.25 / 7.1 | 0.5 / 14.2 | 0.25 / 0.19 | 25 / 11.3 | 150 / 68.0 |

| MX-1 | 1.0 / 28.3 | 2.0 / 56.6 | 1.0 / 0.75 | 100 / 45.4 | 800 / 362.9 |

| MX-3 | 3.0 / 85.0 | 6.0 / 69.9 | 1.0 / 0.75 | 350 / 158.8 | 860 / 390.1 |

| MX-5 | 5.0 / 141.6 | 10.0 / 283.2 | 1.0 / 0.75 | 500 / 226.8 | 1000 / 453.6 |

| MX-10 | 10.0 / 283.2 | 20.0 / 566.3 | 1.5 / 1.12 | 750 / 340.2 | 1150 / 521.6 |

| MX-15 | 15.0 / 424.8 | 30.0 / 849.5 | 2.0 / 1.49 | 1000 / 453.6 | 1500 / 680.4 |

The above power requirements are generalizations that may not apply to your application. Please consult factory.

WARNING: In order to clearly show details of machines, some covers, shields, doors and guards have either been removed or are shown in the open position in photographs throughout this brochure. All protective devices must be properly installed before operation of equipment. Failure to do so may result in personal injury and/or damage to the machine components.

See Rotary Batch Mixer Series for larger maximum batch sizes — 10 to 600 cu ft (0.28 to 17 m3).

FLUIDIZED BED MIXERS

Mix low- to medium-density bulk materials, including liquid additions, in 30 seconds (typical) minimizing degradation of friable materials.

MUNSON Fluidized Bed Mixers are offered in capacities from 0.21 to 280 cu ft

(5.90 liters to 8.01 m3). Model MF-5-SS 4.24 cu ft (0.120 m3) shown.

MUNSON® Fluidized Bed Mixers are recommended when mixing low- to medium-density materials (≤50 lbs/cu ft or ≤800 kg/m3) ranging from powders to pellets — particularly friable materials — with or without liquid additions, in applications requiring short cycle times, relatively gentle product handling and infrequent wash downs.

The MUNSON Fluidized Bed Mixer is among the fastest of all mixers, with cycle times of 10 seconds to two minutes, with 30 seconds typical, yielding a ~5% CV (coefficient of variation).

Flat, angular paddles with overlapping paths effectively sweep material from two parallel U-shaped troughs toward the center and upward, causing it to become airborne in a "fluidized zone" above the longitudinal centerline of the mixing chamber, where discreet particles of batch ingredients readily intersperse, regardless of disparities in particle size, shape or bulk density.

The fluidized zone is also an ideal location in which to spray high- or low-viscosity liquids, which disperse more readily and can be added in relatively high volumes while maintaining free-flowing characteristics of the batch.

This fluidized mixing action also creates less shear than other agitated blenders which, together with extremely short mixing times, results in less product degradation.

The fluidized bed mixer also discharges more rapidly, through its full-length, drop-bottom gates, allowing material to empty from the machine rapidly.

And whereas ribbon, paddle and plow blenders leave a pronounced "heel" of material in the trough following discharge, the fluidized bed mixer evacuates a much greater percentage of material, reducing the need to manually remove — and waste — material between product changeovers.

The MUNSON Fluidized Bed Mixer is configured with two counter-rotating shafts turning paddle agitators rapidly within two, parallel U-shaped troughs.

Specifications

(Click here for model dimensions)

| Model | Volume cu ft / m3 |

Rotor RPM | Rotor Diameter in. / mm |

||||

|---|---|---|---|---|---|---|---|

| MF-.25 | 0.21 / 0.0059 | ||||||

| MF-.75 | 0.71 / 0.0201 | 95 | 10.24 / 260 | ||||

| MF-2 | 2.12 / 0.0600 | 67 | 14.57 / 370 | ||||

| MF-5 | 4.24 / 0.1200 | 54 | 18.11 / 460 | ||||

| MF-7 | 7.1 / 0.2010 | 46 | 21.65 / 550 | ||||

| MF-12 | 12.4 / 0.3511 | 39 | 26.77 / 680 | ||||

| MF-18 | 17.7 / 0.5012 | 36 | 29.53 / 750 | ||||

DUAL DRIVE |

|||||||

| MF-25 | 26.5 / 0.7504 | 32 | 33.46 / 850 | ||||

| MF-35 | 35 / 0.9911 | 29.6 | 37.40 / 950 | ||||

| MF-50 | 53 / 1.50 | 28 | 42.13 / 1070 | ||||

| MF-70 | 71 / 2.01 | 27 | 46.85 / 1190 | ||||

| MF-85 | 88 / 2.49 | 26.8 | 50.00 / 1270 | ||||

| MF-125 | 127 / 3.60 | 26 | 57.87 / 1470 | ||||

| MF-175 | 177 / 5.01 | 25.6 | 64.57 / 1640 | ||||

| MF-210 | 212 / 6.00 | 25 | 68.11 / 1730 | ||||

| MF-280 | 283 / 8.01 | 24.5 | 75.98 / 1930 | ||||

Technical data can be altered without prior notice. Given measurements and weights must not be used for engineering.

CYLINDRICAL

PLOW BLENDERS

For batch blending of extremely fibrous, interlocking, dense, abrasive or moist/oily materials at higher speeds, with higher intensity, and with more uniform results than possible with trough style Ribbon, Paddle or Plow Blenders.

Cylindrical Plow Blender

Unlike trough-style Ribbon, Paddle and Plow Blenders, MUNSON® Cylindrical Plow Blenders consist of a cylindrical vessel and a mixing shaft that rotates about 4-times faster. The vessel is typically filled to 60 percent of capacity that, together with fast rotation of the mixing shaft, serves to fluidize the material and fill the entire mixing vessel with airborne material, maximizing material transfer rates while minimizing impact and degradation.

As a result, MUNSON Cylindrical Plow Blenders can achieve 100 percent uniform blends of materials in ratios down to one part per thousand, blend significantly faster than trough style horizontal mixers, and handle a greater variety of materials, including extremely fibrous, interlocking, dense, moist, sticky, abrasive, fragile or otherwise poor-flowing materials. Cylindrical Plow Blenders are not, however, recommended for mixing of pastes.

When equipped with spray nozzles, MUNSON Cylindrical Plow Blenders offer an efficient means to coat or agglomerate particles, often with less liquid than would be required with trough-style Ribbon, Paddle and Plow Blenders.

MUNSON Cylindrical Plow Blenders are configured with single or multiple charging ports located on the top of the vessel, contoured access doors on the side, a bottom discharge port, and automated controls.

Although Plow Mixing Elements are typically employed, MUNSON paddle agitators can also be used in cylindrical horizontal blenders.

MUNSON Cylindrical Plow Blenders offer the same selection of drives, discharge gates and shaft seals as Munson's trough style Ribbon, Paddle and Plow Blenders, and the same dust-free operation.

VEE CONE BLENDERS

Mix dry and granular bulk materials, including liquid additions, in 15 to 30 minutes. Gentler and easier to sanitize than agitated machines.

MUNSON Vee Cone Blenders for laboratory and other small batch applications feature a cantilevered mounting system that supports interchangeable vessels in six sizes: 0.25, 1, 2, 4, 8 and 16 quart (0.24, 0.95, 1.89, 3.79, 7.57 and 15.14 liter).

A MUNSON® Vee Cone Blender (also known as a "V Cone Blender" and "V Blender") is comprised of two inclined cylinders that rotate, causing bulk material to fall and converge during half of the rotation, and divide during the other half. This mixing action requires significantly less horsepower/kilowatts than ribbon blenders and other agitated machines.

Smooth internal surfaces, with no internal baffles, shafts or bearings, allow unobstructed material flow, as well as complete discharge through a gate valve. The absence of residual material, together with easy access to internal surfaces through the discharge valve and doors at the ends of the inclined cylinders, allows thorough sanitizing in minutes, preventing cross-contamination between changeovers.

Uniform blends are typically achieved in 15 to 30 minutes with equal efficiency at fill volumes from 100% to 50% of rated capacity, depending on material.

Suitable for dry and granular materials, MUNSON Vee Cone Blenders provide a tumbling action that is gentler than agitated machines in which blades, paddles or plows are forced through stationary material.

Since the gentle action of a MUNSON Vee Cone Blender may be insufficient to break down soft agglomerates, an intensifier bar can be utilized to impart the shear needed to reduce these materials.

A MUNSON Vee Cone Blender can also be equipped with a Liquid Dispersion Intensifier Bar positioned within the mixing chamber to distribute liquids throughout the batch more thoroughly and rapidly, reducing cycle times.

The ultimate in simplicity and cleanability, these blenders are widely used in the pharmaceutical, nutraceutical, food, chemical, plastics, ceramics and powder metal industries.

Models are available with useable capacities from 1 cup (0.24 liters) to more than 200 cu ft (5,663 liters), to USDA, pharmaceutical, and other sanitary or industrial standards.

MUNSON Vee Cone Blenders for laboratory and other small batch applications feature a cantilevered mounting system that supports interchangeable vessels in six sizes: 0.25, 1, 2, 4, 8 and 16 quart (0.24, 0.95, 1.89, 3.79, 7.57 and 15.14 liter).

Specifications

(Click here for model dimensions)

| Model | Blender RPM | Useable Capacity |

|---|---|---|

| VB-.25 | 30 | .27 cu ft (8 qt) / 8 liter |

| VB-.50 | 30 | 0.53 cu ft (16 qt) / 15 liter |

| VB-1 | 30 | 1 cu ft / 28 liter |

| VB-2 | 27 | 2 cu ft / 57 liter |

| VB-3 | 27 | 3 cu ft / 85 liter |

| VB-5 | 20 | 5 cu ft / 142 liter |

| VB-10 | 20 | 10 cu ft / 283 liter |

| VB-20 | 16 | 20 cu ft / 566 liter |

| VB-30 | 15 | 30 cu ft / 850 liter |

| VB-40 | 14 | 40 cu ft / 1,133 liter |

| VB-50 | 14 | 50 cu ft / 1,416 liter |

| VB-60 | 11 | 60 cu ft / 1,699 liter |

| VB-75 | 11 | 75 cu ft / 2,124 liter |

| VB-100 | 10 | 100 cu ft / 2,832 liter |

| VB-125 | 9 | 125 cu ft / 3,540 liter |

| VB-150 | 7 | 150 cu ft / 4,248 liter |

| VB-200 | 6 | 200 cu ft / 5,663 liter |

Technical data can be altered without prior notice. Given measurements and weights must not be used for engineering.

Double Cone Blender configurations also available. Please contact MUNSON® for details.

VARIABLE-INTENSITY BLENDERS

Greater versatility than continuous ribbon/paddle/plow blenders or pug mills: Slow, gentle blending, homogenizing, coating and de-dusting, up to high-intensity, high-shear mixing and lump-breaking of dry materials, dense pastes and slurries — at high rates.

Engineered, constructed and finished to sanitary standards, this MUNSON® model VIM-124-S316

Variable-Intensity Continuous Blender allows rapid, thorough cleaning and sanitizing.

Infinitely adjustable rotor speed, together with variable-pitch paddles, allows fine-tuning of blending action, from slow-speed consistent progression of material through the cylindrical chamber, to high-speed "backwashing" of material through turbulent zones for rapid, high-shear interspersing of particles — with typical residence times of 20 to 30 seconds.

Munson's Variable-Intensity Continuous Blender is based on a horizontal, cylindrical vessel with a single agitator rotating at low to high speed, delivering a wide range of mixing/blending capabilities in high capacities.

Small to large volumes of liquids can be injected through ports strategically located on the vessel, and can be driven into the material rapidly and uniformly.

The agitator is comprised of a large-diameter, solid main shaft equipped with paddles affixed to the main shaft in either of two ways: with threaded paddle shafts that are individually adjustable for pitch up to 180° to impart various degrees of blending intensity, or with permanently fixed and fully seal-welded paddle shafts for sanitary applications.

Shorter residence times of 20 to 30 seconds are typical for dry blends of major ingredients, while longer residence times may be required for critical blends containing minor additives and for materials requiring increased retention for liquid absorption or other conditioning.

An optional weir immediately upstream of the discharge can increase the residence volume as needed for blending of certain dry materials having fluid flow characteristics.

Infinitely adjustable from 50 to 2500 RPM when operated by a variable frequency drive (VFD), the agitator shaft is supported by flange block bearings with mechanical face seals as standard. Optional externally-mounted stand-off bearings are available with air-purged packing gland seals, or block seals of Teflon or UHMW polyethylene, including split designs for sanitary applications and ease of maintenance.

The blender and motor are mounted on a common support base, with multiple "V" belt and sheave drives as standard. Optional gear-reduced drives, synchronous gear belt reduced drives or a combination of both are available to optimize speed and for high-torque requirements. All drives are furnished with complete guarding of rotating members.

For heating or cooling during mixing, optional low-pressure jackets are available, as well as high-pressure jackets constructed to ASME code.

For wash down, water or cleaning solution can be introduced through optional injection ports as the agitator is rotated, and drained through the discharge chute or a separate discharge fitting. The optional weir can also serve to increase the residence volume of liquids injected to dislodge difficult-to-clean materials.

Six models offer maximum throughput of 50 to 3000 cu ft/h (1.4 to 85 m3/h) depending on material characteristics, blend ratios and the residence time required to achieve homogeneity.

The Variable-Intensity Blender is based on a nominal 4-to-1 length-to-diameter ratio allowing high throughput rates for homogeneous blending or conditioning, and is available in carbon steel, #304 and #316 stainless steel, abrasion resistant steel, and a variety of exotic materials.

.jpg)

Carbon steel model VIM-124-MS shown with multiple "V" belt and sheave drive arrangement. Injection ports allow liquid additions during mixing, and cleaning solutions during wash down.

Specifications

(Click here for model dimensions)

| MODEL NUMBER | LENGTH (IN/MM) | INTAKE OPENING (IN/MM) | DISCHARGE OPENING (IN/MM) |

|---|---|---|---|

| VIM-83 | 44 / 1118 | 4 x 4 / 102 x 102 | 4 x 6 / 102 x 152 |

| VIM-124 | 61 / 1549 | 6 x 6 / 152 x 152 | 6 x 8 / 152 x 203 |

| VIM-165 | 76 / 1930 | 8 x 8 / 203 x 203 | 8 x 10 / 203 x 254 |

| VIM-206 | 94 / 2388 | 12 x 12 / 305 x 305 | 12 x 12 / 305 x 305 |

| VIM-368 | 135 / 3429 | 14 x 14 / 356 x 356 | 14 x 14 / 356 x 356 |

ROTARY

CONTINUOUS MIXERS

Slash capital and operational costs when blending long runs of dry bulk solids with or without liquid additions, quickly, uniformly and gently

Rotary Continuous Mixer model CM48x12SS with rotating drum of 48 in. (1,220 mm) diameter x 12 ft (3.66 m) in length, is constructed of stainless steel finished to sanitary standards. Stationary discharge shown above.

The MUNSON® Rotary Continuous Mixer cuts labor and operational costs dramatically when mixing dry bulk solids, with or without liquid additions, in-line over long product runs. Delivers uniform blends — typically in one to two minutes residence time — gently and with low energy use.

- Low cost mixing of long product runs

- Low labor costs compared to batch mixers

- Gentle action prevents material degradation

- Accurate blend ratios to 99.9%

- Rapid mixing: 1 to 2 minutes residence time typical

- Lowest energy use per amount of material blended

- Stationary inlet and stationary outlet allow for hard piping

- Handles abrasive and corrosive products, and materials with high bulk densities

- Automatic material evacuation at the end of product runs using an optional reversing discharge weir

- Small footprint per amount of material processed

- Industrial and sanitary designs, construction and finishes

- Long life with minimal maintenance

A money-saving machine for mixing of bulk materials in large volumes, the MUNSON Rotary Continuous Mixer blends primary bulk ingredients, minor ingredients down to 0.1 percent, and/or liquid additions and coatings — uniformly, gently, rapidly and dust-free.

In an automated system, the MUNSON Rotary Continuous Mixer typically requires only a portion of a single operator's time to monitor the machine, unlike batch mixers that can require multiple operators to stage materials, feed the machine and unload it.

The first dry process mixer purpose-built for continuous operation, it features a stationary inlet, a stationary outlet, and a rotating drum with smooth interior surfaces and proprietary mixing flights that mix dynamically with every degree of drum rotation.

Only a small electric motor is required to rotate the drum at a constant 8 to 10 RPM, saving on initial cost and power consumption.

The low speed yet highly-efficient tumbling action — with no impeller or agitator — cuts residence time for most materials to only 1 to 2 minutes which, together with smooth interior surfaces, produces homogeneous blends more gently than any comparable machine.

To achieve homogeneous blends, an accurate metering system is required to feed ingredients into the stationary material inlet. Material depth is generally set at 25 to 30% by means of a "weir" (dam) at the discharge end of the drum, with residence time and the amount of blended material overflowing the weir determined by the residence volume of the rotating cylinder and the rate of material inflow.

Residence times generally range from one to two minutes. Longer residence times may be required for critical blends containing minor additives, or for materials that require increased dwell time for absorption or other conditioning.

For liquid additions and coatings, an optional spray line mounted above the material bed, sprays liquid onto the cascading material, assuring that every particle is exposed to the spray pattern, yielding uniform coatings.

Proprietary mixing flights produce a gentle yet efficient back-flow mixing action free of dead spots or internal restrictions. Optional piping (shown) through discharge end feeds liquids through nozzles onto continuously moving material for rapid, thorough coating.

Back flow mixing action distributes ingredients rapidly, uniformly and gently.

Specifications

(Click here for model dimensions)

| MODEL NUMBER [DIA (IN.) X LENGTH* (FT)] |

1 MINUTE PRODUCT RESIDENCE (CU FT/HR)/(M3/HR) |

2 MINUTE PRODUCT RESIDENCE (CU FT/HR)/(M3/HR) |

POWER REQUIREMENTS (HP/kW) |

|---|---|---|---|

| CM-16x4 | 85 / 2.4 | 42 / 1.2 | 0.50 / 0.37 |

| CM-24x6 | 280 / 7.9 | 140 / 3.9 | 1 / 0.75 |

| CM-36x9 | 950 / 26.9 | 475 / 13.5 | 3 / 2.24 |

| CM-48x12 | 2100 / 59.5 | 1050 / 29.7 | 7.5 / 5.59 |

| CM-60x12 | 3500 / 99.1 | 1750 / 49.6 | 15 / 11.19 |

| CM-60x15 | 4200 / 118.9 | 2100 / 59.5 | 20 / 14.91 |

| CM-72x18 | 7600 / 215.2 | 3800 / 107.6 | 25 / 18.64 |

| CM-72x20 | 8400 / 237.9 | 4200 / 118.9 | 30 / 22.37 |

| CM-72x24 | 10000 / 283 | 5000 / 141.6 | 40 / 29.83 |

Not sure which machine style will suit your application? Do you have a tough-to-figure process and need a second opinion? Our experienced sales engineers will be happy to help you find the answers.