Click to enlarge(L-R) Munson SCC 30 rotary cutter, Munson #4 rotary knife cutter

Click to enlarge

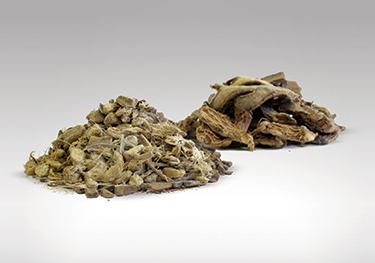

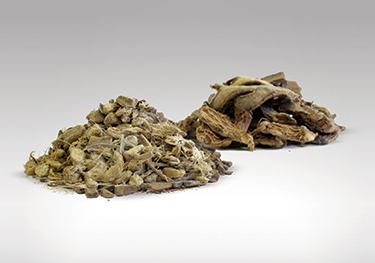

Click to enlargeGinger root, cassia bark and cola nuts are conveyed by rigid auger through a magnet and into the Munson knife cutter.

Click to enlarge

Click to enlargeSCC 30 rotary cutter grinds vanilla beans at rate of 3000 lb per hour.

Click to enlargeSCC 30 rotary cutter contains helical rotor assembly of dozens of interconnected parallelogram shaped cutters.

Click to enlargeGrinding area houses a rotary cutter, rotary knife, hammer mill and roller mill on a mezzanine.

Click to enlargeOn the floor above the size reduction equipment, raw materials are emptied into bag dump stations with exhaust hoods which feed the rotary cutter and hammer mill, and a screw auger (center) that feeds the rotary knife cutter.

Click to enlargeGinger root, cassia bark and cola nuts dumped into this auger conveyor are fed at a controlled rate into the rotary knife cutter.

Click to enlargeSpent fiber is sold as animal feed

Click to enlargeA Munson rotary knife cutter reduces cinnamon and other tough, hard, fibrous roots, nuts and barks.

Click to enlargeGivaudan grinds upwards of 6000 lb (2700 kg) of ginger root per hour into uniform size chips.

Click to enlargeGivaudan grinds upwards of 6000 lb (2700 kg) of cola nuts per hour into uniform size chips.

Click to enlargeA Munson stainless steel SCC 30 rotary cutter reduces 3000 lb (1360 kg) of vanilla beans per hour.