Upon discharge, the 140 cu ft (3.96 cu m) capacity rotary batch mixer evacuates completely with little or no residual, allowing fast, thorough cleaning between batches. Continuous rotation of the drum assures that all materials remain in motion, preventing segregation in batches of varying material densities.

Powders discharge from mixer into hopper and then to bagging machine, which fills 55 lb (25 kg) bags or 2200 lb (1000 kg) bulk bags.

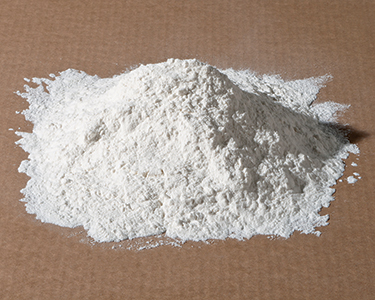

Quality Powder Ltd. custom blends batches that include anywhere from two to 11 types of ingredients with particle sizes ranging from 60 to 300 mesh (250 to 450 microns).